How Automation Is Shaping the Future of Modern Grinding Plants

Grinding Solution

Automation is redefining how industries process raw materials, improve quality and scale production. As technology advances, modern grinding plants are moving away from manual operations and embracing automated systems that ensure precision, consistency and long-term efficiency.

Today, automation is no longer optional; it is a strategic investment that strengthens productivity while reducing human error.

Automation in Modern Grinding Plants

The growing demand for accuracy, throughput and consistent product quality has pushed industries to adopt automation across their grinding operations. In modern grinding plants, automation integrates sensors, control systems, real-time monitoring tools and intelligent process controls that manage everything from material feeding to mill performance and product output.

Automation also enables better tracking of process parameters such as particle size distribution, temperature, airflow, pressure and motor load, all crucial for maintaining stable, high-quality grinding results. As a result, automation in the grinding industry has become a key driver of innovation and competitiveness.

How Automation Improves Grinding Efficiency

Manual grinding processes often suffer from inconsistent feeding, variable mill loads, fluctuating product quality and frequent downtime. Automation eliminates these inefficiencies through:

- Real-time process optimisation that adjusts parameters automatically

- Stable feed-rate control to prevent overloading and underfeeding

- Enhanced mill performance through automated speed, airflow and classifier controls

- Continuous monitoring to detect process deviations before they escalate

- Predictive maintenance to minimise breakdowns

By reducing variability and improving precision, industrial grinding automation allows plants to achieve higher efficiency, lower energy consumption and more reliable throughput.

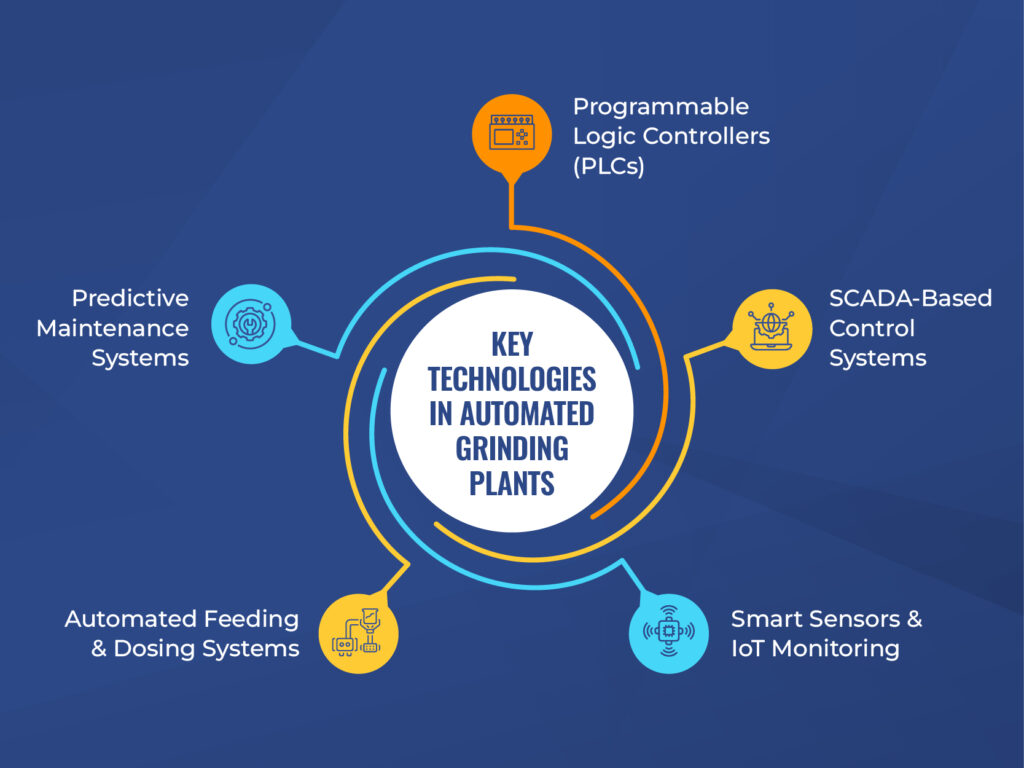

Key Automation Technologies in Automated Grinding Plants?

Automation in grinding systems is powered by advanced technologies that work in sync to deliver accurate and consistent output. Some of the most impactful technologies include:

1. Programmable Logic Controllers (PLCs)

PLCs automate core grinding processes such as dosing, conveying, milling and classification. They ensure stable operation, precise sequencing and real-time control.

2. SCADA-Based Control Systems

Supervisory Control and Data Acquisition (SCADA) systems allow operators to visualise, monitor and control the entire process from a central dashboard. This level of oversight is crucial for automated grinding plants.

3. Smart Sensors & IoT Monitoring

Sensors continuously monitor vibration, temperature, particle size and pressure. IoT connectivity enables remote tracking, troubleshooting and performance optimisation.

4. Automated Feeding & Dosing Systems

These systems guarantee uniform material input, preventing fluctuations that affect product fineness and quality.

5. Predictive Maintenance Systems

AI-driven maintenance tools analyse equipment condition and predict failures before they occur, reducing downtime.

Benefits of Automation in Industrial Grinding Plants

Automation delivers measurable advantages across operations, maintenance and quality performance:

- Higher Productivity

Consistent feeding, stable mill conditions and optimised classifiers lead to higher throughput. - Improved Product Quality

Automation maintains tight control over particle size, resulting in uniform and reliable output. - Reduced Operational Costs

Reduced manual intervention, lower energy usage and optimised machine performance cut operating expenses.. - Enhanced Equipment Life

Predictive maintenance reduces wear and prevents early equipment failures. - Better Safety & Compliance

Automated shutdowns, alarms and controlled operations ensure safer working conditions. - Real-Time Visibility

Plant managers gain instant insight into plant performance, helping them make informed decisions.

RIECO’s Grinding Solutions

At RIECO, we design and deliver turnkey grinding plants equipped with advanced automation technologies that streamline operations end to end. Our solutions integrate:

1. Comprehensive Range of Size Reduction & Classification Equipment

We offer standalone mills to complete grinding systems engineered for precise particle size control across multiple industries.

2. Expertise in Handling Complex & Sensitive Materials

Our grinding solutions efficiently process explosive, abrasive, hygroscopic and heat-sensitive materials with specialised technologies like cryogenic grinding.

3. Advanced Technologies for Precision & Efficiency

We integrate automated controls, optimised airflow systems and high-performance classifiers to ensure consistent quality and superior grinding efficiency.

4. Turnkey Grinding Plants Tailored to Industry Needs

With decades of experience, we deliver fully customised turnkey grinding plants built for reliability, compliance and end-to-end operational performance.

With decades of expertise in industrial grinding automation, we support customers across chemicals, food, minerals, agro-products and speciality materials. Our automated grinding plants are engineered for long-term stability, reliability and performance.

Conclusion

Automation is shaping the future of modern grinding plants by improving efficiency, accuracy and operational control. As industries move towards smarter and more reliable production methods, automated grinding plants will continue to lead the way with consistent output and reduced downtime.

At RIECO, we bring deep engineering expertise and advanced automation capabilities to help industries modernise their grinding operations and achieve sustainable performance.

Contact us to explore our automated grinding solutions for your facility.